- Main page

- About the Company

About the Company

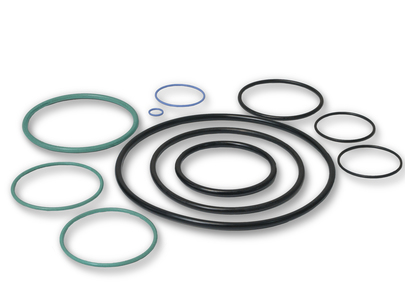

INEL, LLC is a supplier of plastic products and thermoplastic elastomers for more than 20 years.

The company has proved itself as a reliable business partner, having shown the custom-tailored approach in working with clients, the consistent high quality of products, and the compliance with deadlines.

The price policy of the company allows to take into account the business status and economic interests of each consumer.

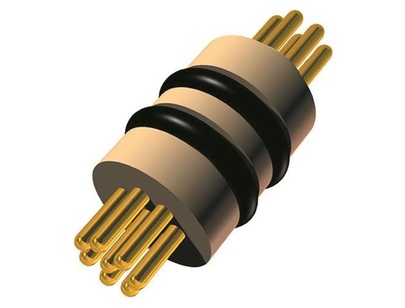

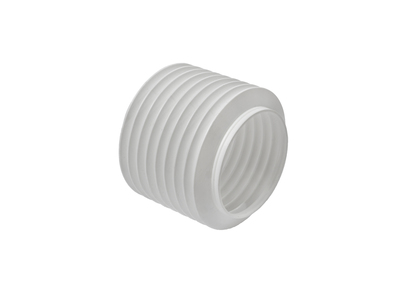

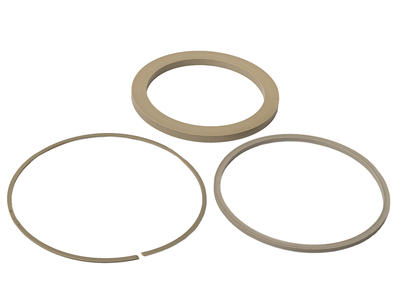

The range of products is represented by the goods for industrial purposes to consumer products, as well as the automotive components.

The skill level of scientific, engineering and operating personnel allows to comprehensively cover the entire production cycle - from the development and design of the product to the manufacture of a part of the required degree of complexity based on the own production.

Maintenance of the equipment in working condition is ensured by systematic preventive repairs of injection molding machines and auxiliary equipment, as well as control measures taken during commissioning.

Our company's specialists will help you to provide the operation of equipment and repair the injection molding machines of various degrees of complexity.

The company's policy is aimed at re-equipment and modernization of the equipment park.

To date, the production is represented by injection molding machines with an effort ranging from 120 to 900 tons and an injection volume of up to 3500 cm3, which allows you to make products from a gram to 3000 grams.

INEL LLC owns a wide range of production technologies. The company's equipment enables to manufacture the products by:

- injection molding, including blanks in the form of pipes and profiles;

- compounding the basic polymer substance with additives and subsequent injection molding into the finished product;

- -machining of blanks (metal and plastic).

In the work we have mastered and actively use:

- general-purpose plastics (polyethylene (PE), polypropylene (PP), polymethyl methacrylate (PMMA), ABS plastics;

- engineering plastics polyamide (PA6, PA6.6, including glass-filled), polyoxymethylene (POM),

- thermoplastic rubbers (SEBS, TPV, TPO),

- thermoplastic polyurethanes (TPU, Covestro, Basf);

- high performance plastics polyether-ketone (PEEK, Zedex), polytetrafluoroethylene (PTFE)

The production base allows you to design molds for parts of various configurations, to produce, as well as to make the repair of tooling.

The company's specialists regularly participate in specialized exhibitions, congresses, forums, actively share experience with colleagues from other regions and countries. New technologies are regularly introduced in the company's research and production facilities. All this allows us to receive large orders for several years, including in import substitution, and maintain the leading position in the industry.

Our partners

Photo Gallery

All photosOur advantages

-

Full production cycle from design to finished products

-

100%

assurance -

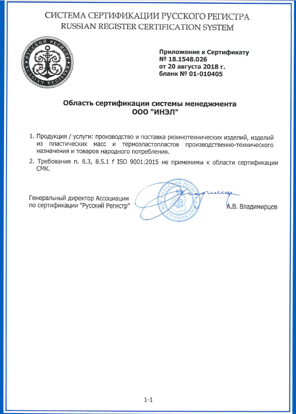

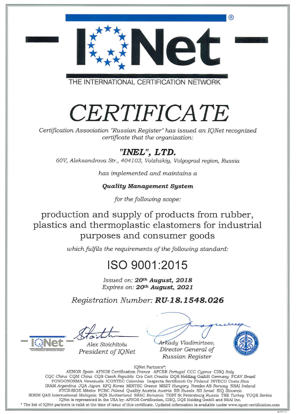

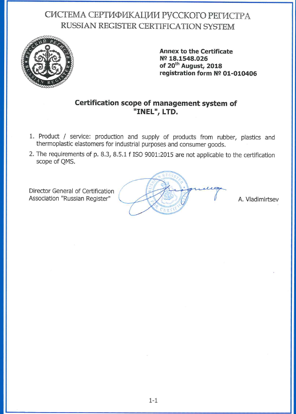

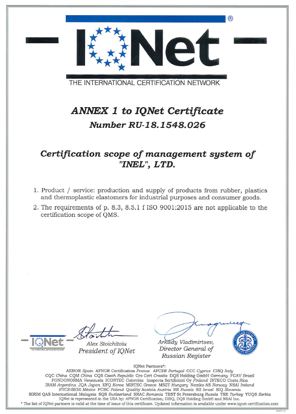

We have the certificate of International Quality Standard ISO 9001:2015

-

Many years of experience and

high-level expertise of employees -

Individual recommendations on the planning and selection of technologies for each customer

didn't find what you were looking for?

Leave a request and our manager will contact you soon